Parts Used

- Ireland Engineering 306 degree cam

- Ireland Engineering double valve springs

- Ireland Engineering heavy duty rocker arms

After building my 2.2L bottom end, I got around to getting my car on

the dyno in the fall of 2009. As I mentioned in other sections of

this site, the performance was very disappointing. Peak RWHP was

about 110HP, I had expected something in the 140 range. I found

part of my problem was with my intake runner length as documented on my

tuned intake project page.

The other problem appears to be the Metric Mechanic sport cam that I

am running. This is a very good cam, possibly the best on the

market for a 320i that still needs to run kjet fuel injection. The

MM cam increases lift and duration at max lift without significantly

increasing duration or overlap. The cam delivers a nice flat

torque curve but does not do much at higher RPMs. I originally

bought this cam back when I was still running kjet and I think it is

time for it to go.

After a lot of thought and discussing my options with several people

I have decided to install a 306 degree duration cam produced by Ireland

Engineering. This cam produces good power over about 3000 RPM with

an expected torque peak between 4000 and 4500 RPM. With the

combination of the longer intake runners, I'm expecting power to drop

off right around the factory redline of 6500 RPM. What I'm

shooting for is most of the benefits of the big cam up until 6500 RPM

with less low to mid-range loss due to the longer intake runners.

Camshaft Removal Tool

The first step was to remove the current camshaft. I wanted to

do this "right" to minimize the risk of damage to either camshaft, it is

pretty easy to snap a camshaft if you are not careful.

I decided to fabricate a copy of the factory cam removal tool.

This tool is a metal frame with eight fingers that contact the rocker

arm eccentrics. The tool is mounted over the valve cover mounting

studs and using the studs the tool is forced down onto the ends of the

rockers compressing the valve springs. This lifts the rockers off

the camshaft.

|

|

|

|

Camshaft removal tool made from angle iron available at any hardware store. |

|

|

|

Bottom view of camshaft removal tool showing fingers that depress the valves and lift the rocker arms off the cam. |

|

|

|

Cam removal tool installed on cylinder head using valve cover studs. |

|

|

|

|

|

Rockers lifted off of camshaft. |

|

|

|

Camshaft then simply slides out. |

|

|

Camshaft Installation The assembly of the head is just

the reverse of the disassembly but it takes time and concentration to

not make mistakes. There are a lot of parts involved and you do

not want to make a mistake on parts placement when installing the rocker

shafts. It took me about 6 hours to complete the assembly sequence

shown below.

|

|

|

|

Ireland Engineering double valve springs installed. Upper keepers are also IE parts designed to fit the dual springs. |

|

|

|

Intake rocker shaft installed in head with the intake rockers. |

|

|

|

Exhaust rocker shaft installed in head with the exhaust rockers.

|

|

|

|

|

|

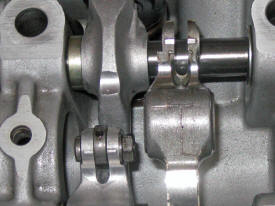

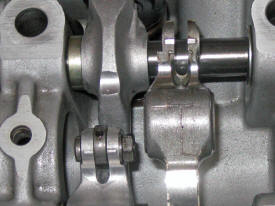

Here is a close up of the bottom of one of Ireland's heavy duty rockers (lower left) compared to a OEM rocker sitting next to it (right) |

|

|

|

Rocker arm retaining collars installed on shafts. |

|

|

|

Last step is to install the new cam using the installation / removal tool I made. |

|

|

After assembling the head, I bolted it back onto the block using the old

head gasket and attached the timing chain. I placed lumps of clay

over the valve pockets on the #1 cylinder to check valve to piston

clearance. I carefully cycled the engine through two full

revolutions (720 degrees) with my adjustable cam gear set to both

extremes of its adjustment range and then removed the head. The

intake valve gets to within about .050 of the piston which is

significantly closer than it used to on my old cam which had about .200

clearance.

|

|

|

|

Clearance check with new cam using clay. |

|

|

|

Cross section of intake valve clearance. There is about .050 clearance. |

|

|

|

The clearance check performed on my old cam. You can see the difference in the intake valve's cross section. There was about .200 clearance with this old cam. |

|

|

Satisfied that there was sufficient clearance, I re-assembled the engine

and adjusted the cam gear to the correct timing for the cam. I

needed about 4 degrees of advance on the cam to compensate for the

amount of material I had removed between multiple millings of the head

and slightly decking the block. |